- 28 March 25

Common Mistakes in Using TMT Saria Resources and How to Avoid Them

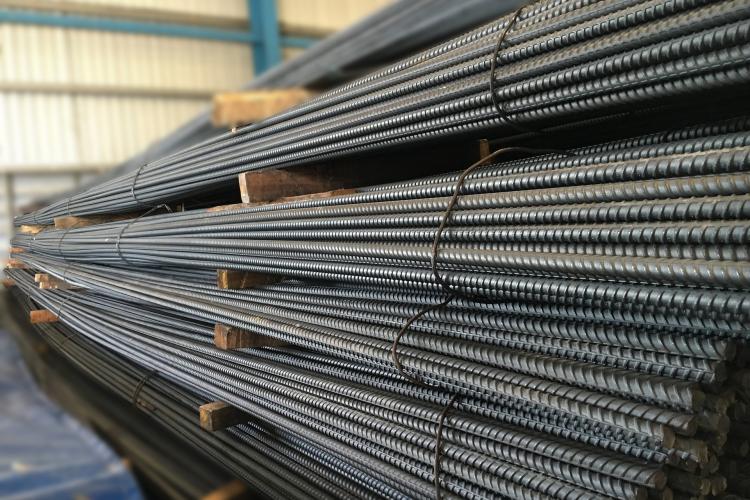

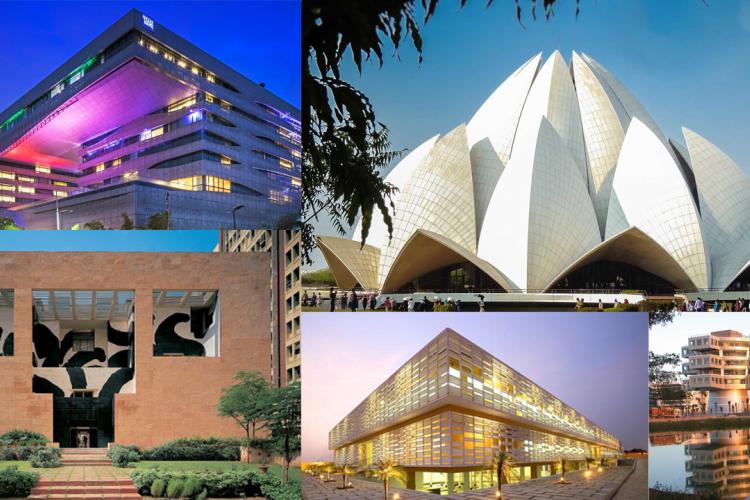

Thermo-Mechanically Treated Saria is a valuable construction material because of its strength and longevity. It can, however, lead to shoddy buildings, lost money, and even safety risks if used improperly. In this article, we outline some of the most common errors individuals make while using TMT Saria and suggest how to avoid them.

Mistakes in Using TMT Saria Resources

- Choosing the Wrong Grade of TMT Saria: Inappropriate grade selection can result in overdesign or structural failure.

- Ignoring Manufacturer Specifications: Disregarding usage guidelines can weaken structural integrity.

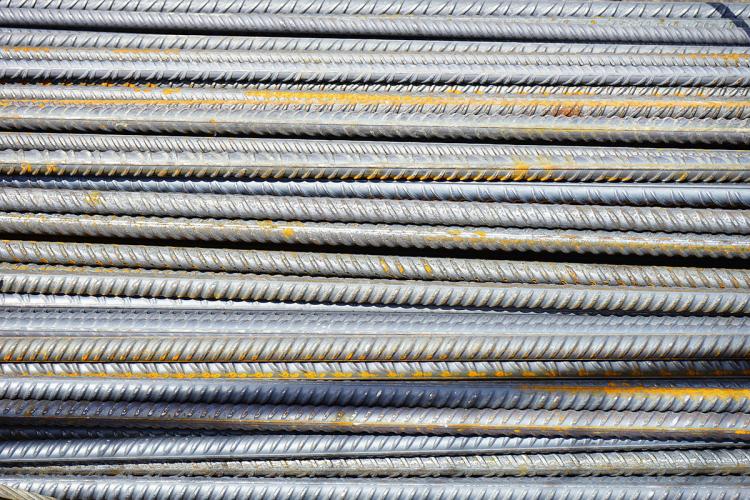

- Improper Storage of TMT Saria: Exposure to moisture leads to rusting and reduced strength.

- Overloading the Structure with Excessive TMT Saria: Leads to cost overruns and inefficient design.

- Incorrect Bending of TMT Saria: Sharp bends weaken the bar and reduce stress resistance.

- Using Low-Quality TMT Saria: Non-certified or low-quality bars jeopardize safety and lifespan.

- Improper Cutting of TMT Saria: Inaccurate cuts can create stress points and material wastage.

- Neglecting Corrosion Resistance: Using regular TMT in high-moisture areas leads to premature failure.

- Incorrect Spacing of TMT Saria: Bad placement affects load distribution and weakens the structure.

- Wasting TMT Saria Resources: Poor planning causes overspending, waste, and project delays.

How to Avoid Mistakes When Using TMT Saria Resources

- Choose the Correct Grade of TMT Saria: Consult engineers and select Fe 500, Fe 550, or Fe 415 as per project needs.

- Follow Manufacturer Specifications: Adhere to provided guidelines for bending, load, and placement.

- Store TMT Saria Properly: Keep in dry, elevated, and covered areas to avoid rust.

- Use the Right Amount of TMT Saria: Refer to structural drawings to avoid under or overuse.

- Bend TMT Saria Correctly: Use appropriate tools and avoid sharp angles during bending.

- Ensure High-Quality TMT Saria: Buy certified bars (e.g., ISI-marked) from trusted suppliers.

- Cut TMT Saria with Care: Use hydraulic/mechanical cutters for precise, safe lengths.

- Go for Corrosion-Resistant TMT Saria: Use in marine or high-humidity environments for extended durability.

- Maintain Proper Spacing: Follow exact spacing and alignment from structural plans.

- Efficiently Use TMT Saria Resources: Use software/planning tools to calculate optimal quantities.

While TMT Saria is a strong and durable material for reinforcement in construction, incorrect application and handling kill. Avert such errors and follow the above-recommended best practices for maximum utilization of TMT Saria material in order to transform your projects into safe and durable ones. Correct reinforcement involves proper planning, quality resource material, and strict compliance with the manufacturer's instructions.

24 May 25

24 May 25