- 26 Jan 26

Top 5 Benefits of Corrosion-Resistant TMT Bars in Construction

A crack in the wall today. A structural failure tomorrow.

The majority of buildings fail silently from within rather than due to design defects. The true foe? Corrosion. Every drop of moisture, every salty breeze, and every monsoon season gradually erodes ordinary steel, weakening your building's foundation. Consequently, compromises are no longer acceptable in modern construction.

SRMB Steel's corrosion-resistant TMT bars are designed to prevent rust, increase structural longevity, and safeguard your investment for many years. This isn't just another choice if you're looking for the best TMT Bars for construction. This choice is prudent.

What are the Benefits of the Corrosion-Resistant TMT Bars?

Whether you go with 8 mm or 12 mm TMT Bars, the first thing to take into account is the price per kg. Then consider the benefits. Here are top 5 benefits which make them the best TMT Bars for construction.

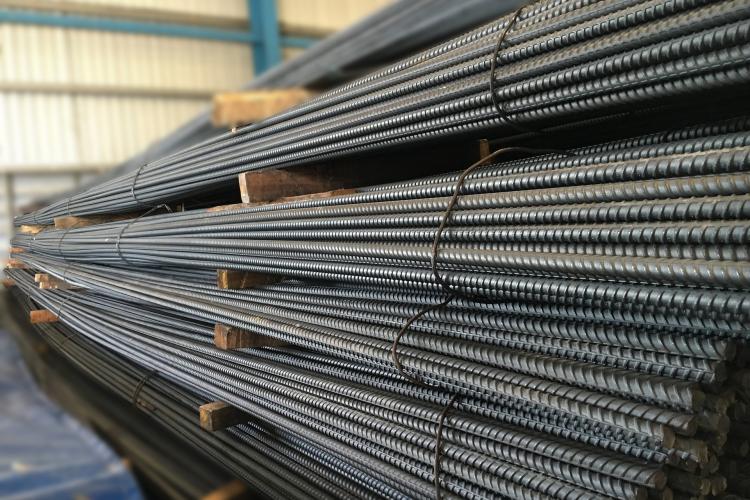

Superior Corrosion Protection

Corrosion has long-lasting and structural effects even though it is brought on by moisture, salty air, and monsoon humidity. Low-carbon steel chemistry and controlled thermo-mechanical treatment are used in the engineering of SRMB's corrosion-resistant TMT bars. This technique significantly reduces oxidation pathways. As a result, rust develops far more slowly, maintaining the integrity of the reinforcement for decades.

This benefit directly translates into lower maintenance costs and longer structural life for builders in coastal or high-humidity areas. Over the course of the facility's useful life, it works similarly to an initial investment that brings in returns.

Enhanced Safety and Structural Lifespan

Corrosion-resistant TMT bars maintain their mechanical performance for a longer period of time. Rusting bars can weaken the bonded zones between steel and concrete, cause spalling, and cause cracks as reinforced concrete ages. SRMB’s corrosion-resistant TMT bars preserve this bond to the protected surface and optimised microstructure. This ensures consistent strength where it matters most and makes it the best TMT Bars for coastal constructions.

Economical in the Long Term

High-quality 12 mm TMT Bars price per kg may be more expensive initially, but their lifetime costs are far greater. The rationale is that decreased corrosion results in fewer repairs, longer intervals between major maintenance cycles, and less need to replace reinforcement.

Before choosing any TMT Bar, take into account the cost of structural retrofits, repair teams, or downtime. The savings quickly overshadow the increase in material costs. This effect is even more noticeable in areas subjected to severe monsoons or salty conditions.

Built for Indian Conditions and Compliance

SRMB TMT bars are made for the diversity of Indian climates in addition to being corrosion resistant. From humid coastal belts to industrial pollution and monsoon rains, these bars withstand environmental stress while delivering robust mechanical performance. With these environmentally friendly products and compliance, SRMB emerges as the best TMT bar company in India.

Each of these TMT Bars is best for everything from housing to civil infrastructure and high-rise construction.

Smooth Workability at the Site

Technical performance should never come at the expense of constructability. This is why SRMB provides corrosion-resistant TMT bars that have outstanding on-site weldability and bendability. Because of their fine microstructure and low carbon content, these TMT Bars are best for increasing workability in construction. This reduces fabrication difficulties and promotes schedule discipline, especially in complicated designs or retrofit projects.

Engineers and contractors report that high-quality TMT bars are consistently easier to handle, reduce rework, and improve bonding with concrete. These all enhance general quality and safety.

Bonus: Understanding 12 mm SRMB TMT Bar Price Per Kg

A crucial component of construction procurement is budget planning. You should be aware that market conditions and logistics cause price fluctuations. According to the SRMB price list, the 12 mm TMT Bar price per kg is ₹75.10, which reflects its value proposition among premium TMT bar offerings.

This makes it a competitive option when weighing initial material costs against long-term durability, lower maintenance, and structural value.

Why SRMB Is Considered the Best TMT Bar Company in India

SRMB has established itself as the best TMT bar company in India with its WINGRIP technology. This technique provides high tensile and ductility in 550 D and strengthens the concrete bond. Its corrosion-resistant TMT bars are developed from intricate thermomechanical processing to raw material selection, rather than being an add-on.

These qualities translate into dependability, performance, and peace of mind for developers, contractors, and dealers searching for the best TMT Bars for construction.

Final Imprint

Corrosion resistance isn’t just a material property. It’s an investment in performance, durability, and lifecycle savings. Choosing corrosion-resistant TMT bars from SRMB means building smarter. With these steel bars you can build a structure in Indian environment that ensure the test of time.

Whether you’re planning residential apartments, commercial complexes, or major infrastructure projects, SRMB’s corrosion-resistant TMT bars deliver everything. Be the strength, durability, or cost efficiency that holds your dream without any corrosion.

FAQs

TMT bars from the SRMB are specially treated to resist corrosion. With tempcore technology these bars are made from Indian environments where moisture and saline water are common. In addition, these bars have a WINGRIP-rib pattern which enhances the bonding with concrete so that your dream structure can stand the test of time.

Salt spray testing is a primary testing technique. This test shows and assesses a component's or material's resistance to corrosion after prolonged exposure to a salt spray. Salt spray testing needs to be done in a controlled setting, like a closed salt fog tank, in order to be effective.

For your dream construction, where durability, high tensile strength, ductility, earth and corrosion resistance matter, you need to opt for SRMB’s 550 D tmt bars. These bars are not only ideal but essential. This makes it the best bar for any construction, irreplaceable for a structure that will last longer.

An open water system typically has a corrosion rate of about 1 MPY. If your corrosion rate is about 10, you ought to do something. You should be concerned if the corrosion rate is 20 MPY or higher because it is "eating" the metal quite quickly.

29 Jan 26

29 Jan 26